7 reasons to use AWES technology

“AWE systems, a new technology that is revolutionizing the generation of wind energy”. An article by Agustín Arjonilla, AWES manager.

06 Sep 2023

From windmills to aircraft-borne kites: the evolution of devices to capture wind energy.

Wind energy is not anything new. The first practical windmills emerged in Persia, possibly in the 7th Century CE. From there it extended to other parts of Asia, and later to Europe. Windmills were used for a variety of reasons, including grinding grain, extracting water and pumping water. Today they are used to generate electricity.

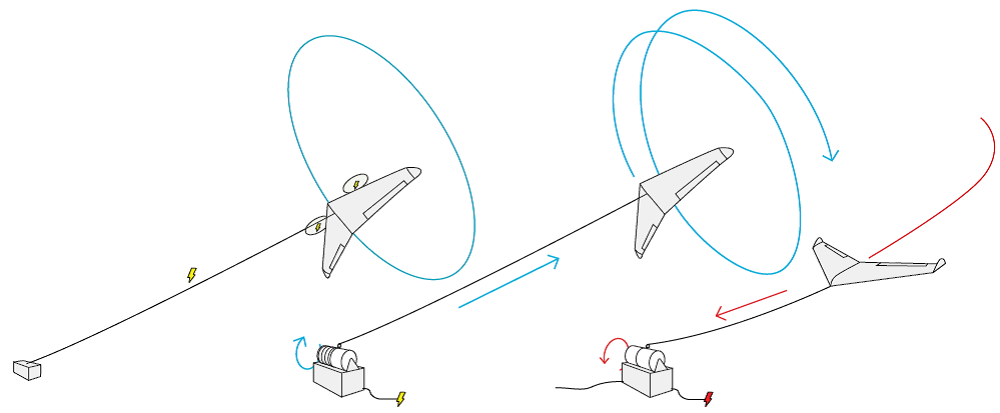

The technological evolution of devices used to capture wind energy has led today to the use of tethered unmanned aerial vehicles (UAV). These aircraft are used to capture wind energy by flying in crosswinds, and their energy is transmitted to the ground; so they could be considered tethered drones. These peculiar drone systems are called Airborne Wind Energy Systems or AWES.

AWES systems combine multiple concepts for the conversion of wind energy into electrical energy using autonomous aerial vehicles connected to the ground with a cable. The two main concepts are: on-vehicle (“fly-gen”) or on-ground (“ground-gen”) power generation:

AWES is still a young technology. The mathematical foundations of what would become AWES were presented in the scientific paper: “Crosswind Kite Power” by Miles L. Loyd in 1980. During the nineties, AWES research was practically abandoned; but in the last decade, the sector has experienced an extremely rapid acceleration. Several companies, mostly small start-ups and university spin-offs, have entered the wind energy business at high altitude, filing hundreds of patents and developing prototypes and demonstrators. Now that drone technology has matured, it has become possible to carry out the various concept demonstrators on AWES that today we can find flying in some parts of the world.

7 reasons to use AWES technology to generate electricity:

1. Enables access to more wind resources.

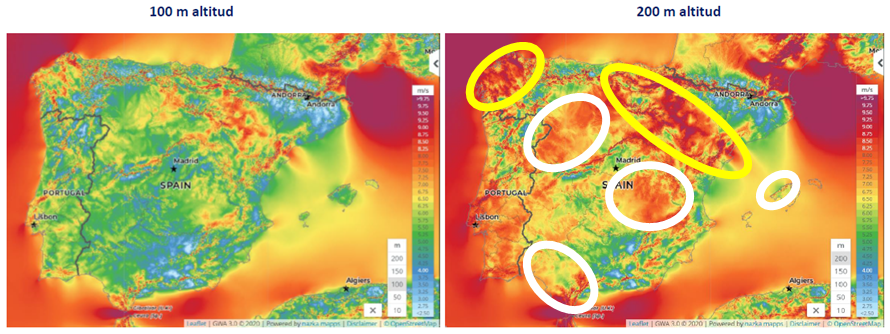

At higher altitudes, wind speed increases, and it does so almost exponentially. For example, the energy density of the wind doubles between 500 and 1500 meters. This translates into the global industrial trend of developing individual wind turbines with increased rated power (up to 5 MW) that have long blade lengths (to increase the swept area) and tall turbine shafts (to achieve stronger winds at higher altitudes); but these will never be able to reach the heights of an AWES. In the case of Spain, AWES would significantly increase both on-shore and off-shore wind resource potential (on the mainland and even more on islands).

Extrapolating the case to the whole planet, it is possible to conclude that a significant part of the world’s primary energy could potentially be extracted from medium and high altitude winds. This means there will be great commercial and research opportunities for the coming years in the field of AWES.

2. Mitigates the problem of intermittent renewable energy sources.

In 2016, Bill Gates called for “energy miracles.” By miracles, he meant new technologies that can help solar PV and conventional wind turbines achieve a faster and more affordable transition to 100% renewable energy that meets needs globally. He was especially looking for technologies that could solve the problem of intermittency of renewable energy sources (when there is no sun or wind there is no solar or wind generation). When asked to name such potential breakthroughs or “miracle” technologies, Bill Gates mentioned high-altitude wind power and called it a “potential magical solution” to the world’s energy problem. In another interview, he called High-Altitude Wind Energy one of the three most promising technologies for renewable energy generation.

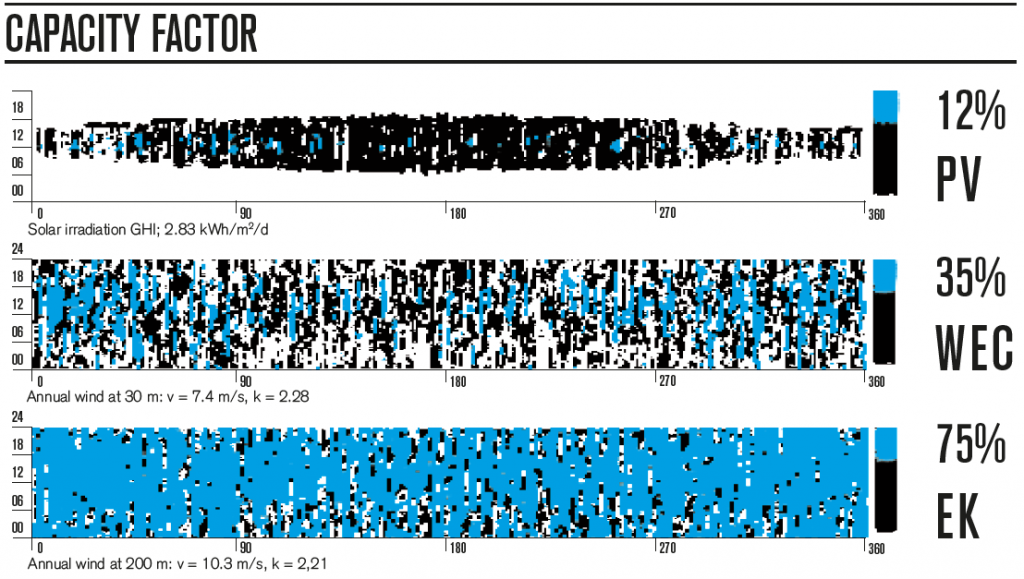

Realistically, we will still have to wait a few years before we have the technologies (especially the materials that make up the cable) to reach heights greater than 500m; but with the current 200 to 500m we can access winds that are above the atmospheric boundary layer, which are less turbulent and more constant and which improve the load factors of current solar and wind generation systems. For example, according to Enerkite’s data for its EK200 system (see graph below), these winds would improve the estimated load factors of both solar photovoltaic (12%) and conventional wind generation systems (35%) by up to 75%:

3. Reduces generation costs (LCOE).

Introducing a new technology into the real world is no easy task, as many barriers to entry must be overcome. When the market considers adopting a new technology, it is because it improves on existing technologies in at least one aspect (e.g. economics, environment, social factors, etc.) and does so in a significant way (e.g. by improving it by at least 50%).

When quantifying improvements in the economics of renewable generation systems, the best approach is to compare the Levelized Cost Of Energy (LCOE). The LCOE represents the sum of the costs of a power generation asset over its lifetime (from construction to recycling) relative to the energy it has produced in that time (€/Mwh).

According to several sources, including the historical series of LCOE analysis carried out by the LAZARD consulting firm, current renewable energies (solar infrastructures larger than 1 MW and onshore wind turbine farms) have a lower LCOE than coal or natural gas plants. Therefore, AWES should be compared with current renewable energies, of which conventional wind turbines have the lowest LCOE given their maturity and period of existence in the market. Since there are no AWES systems in real operation, beyond a few concept demonstrators that operate with a certain degree of autonomy, we cannot consider their operation and maintenance aspects (OPEX); but we can quantify the investment costs (CAPEX) and infer the recycling costs (LCOE).

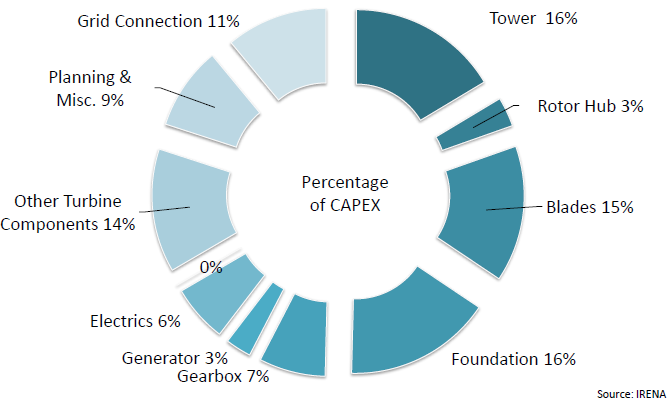

In a conventional wind turbine, 60% of the energy is generated with 30% of the outermost end of the blade; therefore, this can be replaced by an aerial vehicle whose wing area is equivalent to 30% of the blade area to generate the same energy. This transformation into an AWES system achieves a CAPEX saving of 50% in a typical infrastructure (see graph below) by replacing the blades and tower of the wind turbine with an aircraft tethered by a ground cable:

As for the recycling costs, it can be inferred that they are much lower; since the mass of an AWES (e.g. see the data of the European AWES Association in Kg/Mwh in the following graph) is approximately one third of a conventional wind turbine. Therefore we obtain a saving of 66% in terms of the mass of the material to be recycled.

4. Renewable wind power generation reduces carbon footprint.

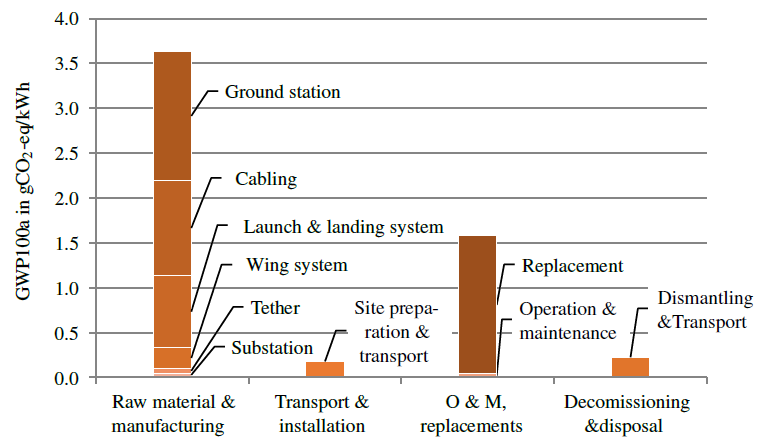

The carbon footprint of a product is an environmental indicator, measured in mass of CO₂ equivalent, which aims to reflect “the total greenhouse gases (GHG) emitted by direct or indirect effect during the life cycle of that product. This indicator has been analyzed in the study: “Life Cycle Assessment of Electricity Production from Airborne Wind Energy” by Stefan Wilhem) based on a theoretical AWES system of 1.8 Mw including all necessary components up to grid connection. As an example case, a generic fixed-wing aircraft with a ground-based generator was considered. This system was then compared to a conventional wind turbine of similar power. The study concludes that the AWE plant studied has a carbon footprint of 49% compared to the conventional wind turbine (see carbon footprint breakdown by elements):

5. Has less visual impact.

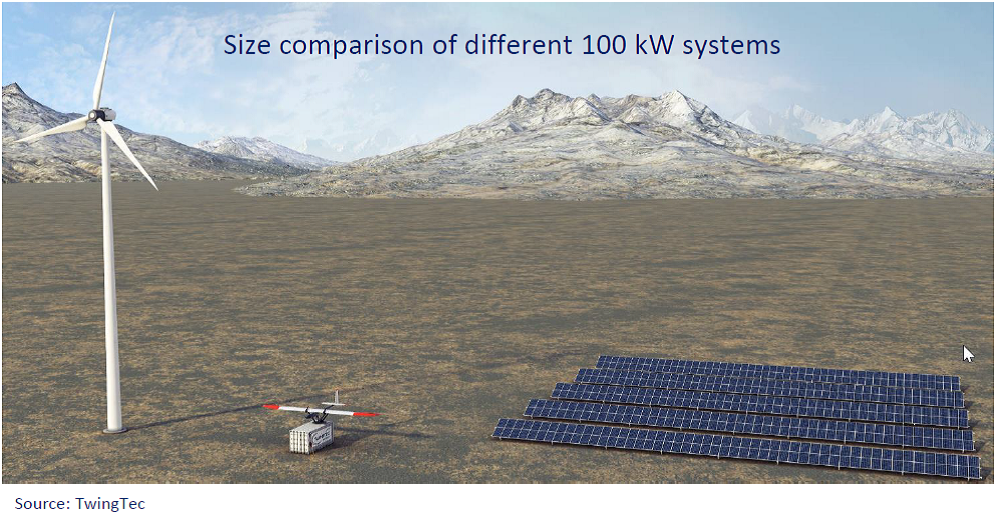

As they say, a picture is worth a thousand words: the visual impact of the different technologies for generating 100 kW is very different.

6. Provides greater flexibility.

AWES provide a renewable generation system that can be installed and uninstalled in minutes and can be easily transported, installed and operated almost anywhere in the world. At the end of the day, an AWES is basically composed of three elements: an aircraft, a ground system and a cable that joins them, which can be “compacted” in a format that even allows it to be easily transported by road. In fact, the multiple AWES concept demonstrators that exist today, usually house all the elements in a container; thus allowing its transport by land, sea or air, easily and efficiently.

Flexibility means logistical advantages that make AWES a very attractive option in cases such as emergencies, military operations, self-consumption or in any isolated (off-grid) and/or remote systems in which they can compete successfully against optimized solutions such as generator sets.

7. Provides greater scalability.

There are now a large number of AWES concepts that have been demonstrated in flight (see the following picture of some European demonstrators). Once the AWES concept demonstrator has been developed, it can quickly be scaled up from a few Kw to several Mw.

At CT, we recognize the great potential of AWES to generate renewable energy. Therefore, in 2020 we started developing the enabling technologies needed for AWES to reach maturity through a collaboration with the Carlos III University of Madrid, who are pioneers in Spain in the development of AWES technologies, and we are designing our own 100% Spanish system focused on the self-consumption market; although we have also established a policy of alliances with more mature system integrators in order to provide solutions to the renewable generation market on a larger scale.

As CT is the leading Spanish company of the European AWE Association, for more than a year we have been launching communication initiatives and concrete actions coordinated with the rest of the European AWES industry, including the European AWES Center of Excellence on the island of La Gomera, the Flight Test Center in CEDER/Soria and our Flight Test Center in Madrid/Castilla León. The Center of Excellence brings together not only the infrastructure for operations, but also offers unique infrastructure for AWES aircraft conceptual design, advanced AWES modeling and simulation and advanced AWES integration environments. In addition, we are already working on proposals for larger scale generation for the national energy industry.

Related Insights

Industrial revamping, the second life of industrial plants in the age of Industry 4.0

“The age of Industry 4.0 has quickened the pace of technological modernisation in factories, leading to rapid obsolescence of machinery and technologies. This shift poses a significant challenge for all industrial sectors. Against this backdrop, industrial revamping emerges as a key strategy to optimise investment and extend the lifespan of existing facilities, presenting a cost-effective alternative to complete equipment renewal”. An article by José Fernández Infantes

Read moreThe power of V2X technology to improve driver assistance and traffic management.

V2X technology, in particular, is a key part of our vision of safer, more efficient and connected transportation. This technology facilitates communication between vehicles, road users and infrastructure, enabling real-time data exchange and communications that are essential to improving road safety and traffic efficiency. An article by Santiago Ferrer, Project Manager.

Read moreEmpowering global connectivity: Designing satellite communications antennas with affordable technologies.

Revolutionizing connectivity with our cost-effective antenna for enhanced satellite communications. An article by Álvaro García Cáceres, project manager and radiofrequency engineer.

Read more